Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

The shift to clean energy is driving an increase in the requirement for metals. The world requires significant volumes of metals and minerals in the decades ahead – according to a recent BHP forecast, two times as much copper, four times as much nickel, twice as much steel, twice as much potash – and so on for the other critical metals and minerals.

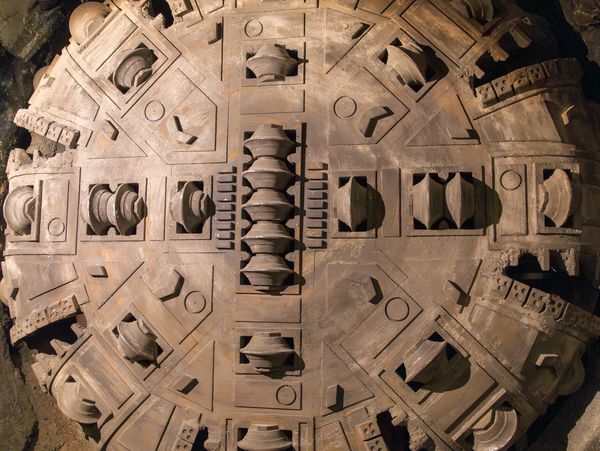

Most of the high-quality ores close to surface have been mined, so the mining landscape into the future will have to be focused on deep mining and zero entry mining. Automation, Robotics and AI will play a key role in enabling deeper mining.

At Intelligent Robotics, we continue to solve some of mining's biggest challenges through our innovative engineering and technologies.

Intelligent Robotics is developing next generation industrial applications to enable robots and humanoids to perform complex, human-like tasks in mining, manufacturing, processing, and service environments.

By integrating advanced AI, computer vision, machine learning, and task-specific apps and agents, we equip robots capable of perceiving, adapting, and operating safely in dynamic industrial environments.

Our teams research emphasises on the ability of advanced robots for real-time decision-making, dexterous manipulation, precise motion control to perform tasks such as equipment servicing, component replacement, inspections, and material handling with accuracy and consistency.

In collaboration with leading mining and industrial partners, we design robotic solutions tailored to specific operational workflows to increase productivity, reduce downtime, improve safety, and streamline maintenance. This industry-driven approach accelerates the deployment of humanoid robots in practical, real-world mining scenarios.

Intelligent Robotics is developing Zero Mine Entry autonomous maintenance systems, built around the concept of AI service agents controlling, vehicles, robots, robotic cranes and dedicated BOTs to perform specific tasks such as inspecting and replacing wear parts, swapping modules and refueling liquids.

Our robotic automation solutions can help you streamline your processes, improve efficiency, improve safety, and reduce costs. We offer a range of automation services including custom robotics, AI, and advanced sensing

Intelligent Robotics Pty Ltd

Suite 3A d’Albora Marina The Spit Spit Road Mosman New South Wales 2088 Australia. ABN 91 673 184 775

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.